AQ Assured by AsureQuality, New Zealand's Government-owned food assurance company.

Theland A2 β-casein Whole Milk (1L )

PRODUCT ATTRIBUTES VERIFIED BY AQ ASSURED

- 100% Australian Made

- Contains A2 Beta Casein

- Made from 100% raw milk

- 100% Fresh UHT Milk

- No added colours

- No artificial flavours

- No preservatives

- No added sugar

- Family Pack

Origin

Origin

This product is 100% Australian made.

The raw milk used in the production of the A2 product, is sourced from selected dairy farms within the south-eastern corner of Australia.

The cows naturally produce the A2 β-casein milk protein.

Theland Supply Chain

There are systems in place throughout the supply chain to ensure that each carton of milk meets high standards of food safety and quality.

Select into any part of the supply chain to view the verified activities and assurances at each step.

The Farm

Farm Assurances- A2 Milk

The raw milk used in the production of the A2 product, is sourced from selected dairy farms within the South-Eastern Corner of Australia.

The herds supplying the milk naturally produce the A2-β casein milk protein.

Routine surveillance and monitoring of the raw milk supply from the farm ensure ongoing compliance.

Farm Assurances- Animal Welfare

All animals must be clearly identified through the National Livestock Identification System (NLIS) - Australia's system for identifying and tracking dairy cattle.

Farms must meet their obligations under the Australian legislation including the Australian Animal Welfare Standards and Guidelines for Cattle (2014) to ensure that all aspects of animal health and welfare are considered. This includes performing health checks on the animals and having systems in place to isolate any unhealthy animals from the herd.

The animals must have access to fresh, clean water at all times. This includes providing to water to the herd when grazing on paddocks and near the milking sheds.

The farm must provide the herd with adequate protection from extreme heat or cold temperatures, protection can include topographical features such as hedges and trees that provide shelter.

Farm Assurances- Milk Supply

All milk supplier farms are required under the Dairy Act 2000 to be licensed with the relevant State Authority.

In Victoria this is Dairy Food Safety Victoria (DFSV) and in New South Wales this is the (NSW) Food Authority.

The farms must comply with the conditions of the licence which includes:

- Demonstrating compliance with the relevant provisions of the Australia New Zealand Food Standards Code.

- Having a food safety program which is routinely audited by the relevant State authority.

- A requirement to filter and chill the milk to below 5°C within 3.5 hours from the start of milking to ensure freshness and prevention of microbial growth.

- Keeping milk chilled while stored on the farm awaiting collection.

Farm Assurances- Water Use

Water used in the milking shed must be suitable for use and the farm should hold records of any testing.

Dairy Carriers-Assurances

Dairy carriers (milk tankers) are required under legislation to comply with provisions within The Food Act 1984, The Dairy Act and The Australia New Zealand Food Standards Code (FSANZ).

Regulatory controls include:

- The dairy carrier must adhere to a documented food safety program through all stages from collection, transportation, and delivery.

- Prior to collecting the milk at the farm, the tanker driver is responsible for taking a sample of the milk.

- The milk is transported to the factory in tankers which maintain the temperature of the chilled milk.

- Keeping records to ensure traceability of milk. This includes the tanker details, date and time of milk collection, temperature of milk, description and quantity of milk collected and delivery destination.

- Once the delivery is made the tanker is cleaned in place (CIP) with approved chemicals and potable water.

Dairy Carriers-A2 Assurances

Dedicated tankers collect the milk from the selected A2 milk supply farms.

The driver takes a sample from each farm and delivers it back to the factory where it can be tested to ensure compliance to the required specification.

The Factory

Factory Assurances

On arrival at the factory a sample of the chilled milk is taken from the tanker and checked for quality.

The milk is not accepted if it fails to meet required specifications.

The raw A2 milk is kept segregated in dedicated silos.

Once approved for use, the milk is standardised, and heat treated to achieve commercial sterility.

The milk is aseptically packed into individual tamper-proof Tetra Pak cartons.

Each brick (individual unit) is individually coded for traceability.

Regulatory Assurances

The Export Control (Milk and Milk Products) Rules 2021 require that water used within the factory must be potable.

Water potability standards are prepared by the National Health and Medical Research Council and activities must be undertaken to verify the quality of water against the Australia Drinking Water Guidelines.

In addition to company- based testing, samples of finished product are collected by DFSV auditors during routine audits and are assessed through the DFSV product surveillance program.

The dairy factory is regularly audited to ensure it complies with the regulations which include:

- The Dairy Act 2000

- The Food Act 1984

- The Australia New Zealand Food Standards Code (FSANZ)

- Dairy Food Safety Victoria (DFSV).

The factory must be registered with the Department of Agriculture and Water Resources and meet the requirements of The Export Control (Milk and Milk Products) Rules 2021.

A declaration of compliance statement must accompany each shipment attesting that the product is:

- Eligible for export.

- Fit-for-human consumption.

- Meets any specific importing country requirements.

Finished Product Testing

Samples from each batch of finished product are tested* for compliance to specification prior to release.

Testing includes a range of chemical, microbial, and sensory attributes to ensure that food safety and quality requirements are met.

*(The protein composition is tested by the laboratory to ensure that the level of A1β-casein protein is below the quantification level of the analytical method used.)

Shipping

Shipping Assurances

The shipping company must ensure that the products are accompanied by all EAD (export accompanied documents) that are required by the importing country, including:

- customs documents

- health certificates

- certificates of laboratory testing analysis

All other documents that are required by the importing country must be completed and approved before the container is sealed and loaded on board the ship.

The product is shipped to China and checked by China Customs on arrival. China Customs check the import documentation to confirm all requirements have been met and may test the product again prior to releasing it into the country.

Once cleared by Customs the product is sent to the warehouse.

Retail

Retail Assurances

The product arrives at the warehouse where it is managed using barcoding and traceability systems.

Product is loaded onto delivery trucks and distributed to individual shops, supermarkets, and other customers.

The AQ Assured brand and QR code can be scanned to provide consumer confidence of the food safety and quality measures undertaken throughout the supply chain.

Environmental

Environmental

The Farm-water use.

To ensure the ongoing sustainability of the resource, water used on farms is allocated and regulated by the relevant State and Territory Government.

Dairy Farmers have many options to conserve water including the use of low - pressure hoses, quickly fixing leaks, and reducing evaporation from water stores.

The Farm-waste management.

To improve on farm productivity whilst minimising environmental impact, farmers must comply with the regulations contained within the Environmental Protection Authority (EPA), including the management of waste.

This is to ensure that effluent is contained within farm boundaries and does not enter water supplies or contaminate land.

Social & Ethical

Social & Ethical

Animal Welfare

Farmers must meet their obligations under legislation including The Australian Animal Welfare Standards and Guidelines for Cattle to ensure that all aspects of animal welfare are considered in relation to the following five provisions:

- Nutrition: the animals must be provided with access to fresh water and a good diet.

- Environment: shade or shelter must be provided to give protection to the animals from extreme weather conditions.

- Health: prevent or rapidly diagnose and treat illness or injury.

- Behaviour: the animals must be provided with conditions that allow natural patterns of social behaviour.

- Free from distress: to live and grow in a safe environment.

Safety & Quality

Safety & Quality

The safety and quality of the milk is ensured through systematic identification and management of hazards throughout the supply chain:

- Animals are clearly identified to ensure traceability via the National Livestock Identification registration system. (NLIS)-add link.

- Farms are registered and licensed with the relevant State Authority. This includes the requirement to have an audited food safety program.

- A2 milk is collected from selected cows that produce the A2 β-casein milk protein.

- Milk is only collected from healthy animals.

- Samples of milk from the A2 dairy farms are collected for testing at the laboratory as part of an ongoing routine surveillance program to ensure compliance to the required protein composition.

- The milk is chilled on farm to below 5 °C within 3.5hours from the start of milking.

- To maintain freshness, the milk is kept chilled on the farm until it is collected.

- Speciality, dedicated A2 milk tankers collect the milk from farm.

- The milk tankers operate under a documented food safety program to ensure safety from collection through to delivery.

- On arrival at the factory a sample of the milk is removed from the tanker and evaluated for quality.

- The A2 milk is kept in segregated speciality silos before being processed to strict specifications. (this includes standardisation and UHT sterilisation).

- The milk is tested throughout production to ensure its meets specifications and regulatory compliance.

- The factory holds accreditations to ensure compliance to all relevant legislation including The Food Act, The Dairy Act and DFSV requirements.

- The factory also ensures the milk is manufactured in accordance with the requirements in the Export Control (Milk and Milk Products) Rules 2021.

- Each batch of finished product is tested to ensure that it meets the required specification including testing the protein composition.

- The product meets the overseas market access requirements (OMAR) of the countries to which it exports.

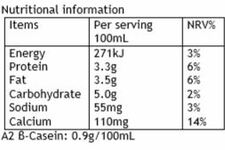

Nutrition

Nutrition

100% Australian Cow’s Milk

The raw milk is sourced from cows that naturally produce the A2-β casein protein.

Theland A2-β casein whole milk (1L) contains no added colouring agents, sweeteners, gelatin, or preservatives.

This product contains calcium, an important source of nutrition for building strong, dense bones early in life, and keeping bones strong and healthy in later life.

This product contains 100% natural protein. Protein is important for the growth and repair of the body’s cells and for building muscle.

The stated level of protein is based on a calculated average, actual protein levels may vary slightly between batches.